Our technical equipment

Enter the backstage of Chartres en lumières!With Chartres en lumières, the spectator is invited to wander through the streets of Chartres to discover the city's key sites, illuminated and set to music by numerous scenographers.

But which installations are behind this unique event?

Lighting technology

The scenographies of Chartres en lumières propose static or animated creations. Each type of scenography uses different techniques.

The static illuminations

This technique consists in the projection of a glass slide worked with heat (technique used for the work of the stained glass), via an overhead projector. This technique is used for the illuminations of the Eurelium, the quay and the Gloriette wash houses.

The animated scenographies

This technique uses the video mapping technique. Based on the architectural lines of the monuments, the videos unfold a scenario inspired by the monument, its history, its architecture. The animated scenographies are accompanied by a soundtrack. The lamps used operate with xenon or mercury and project HD digital images, stored on server media.

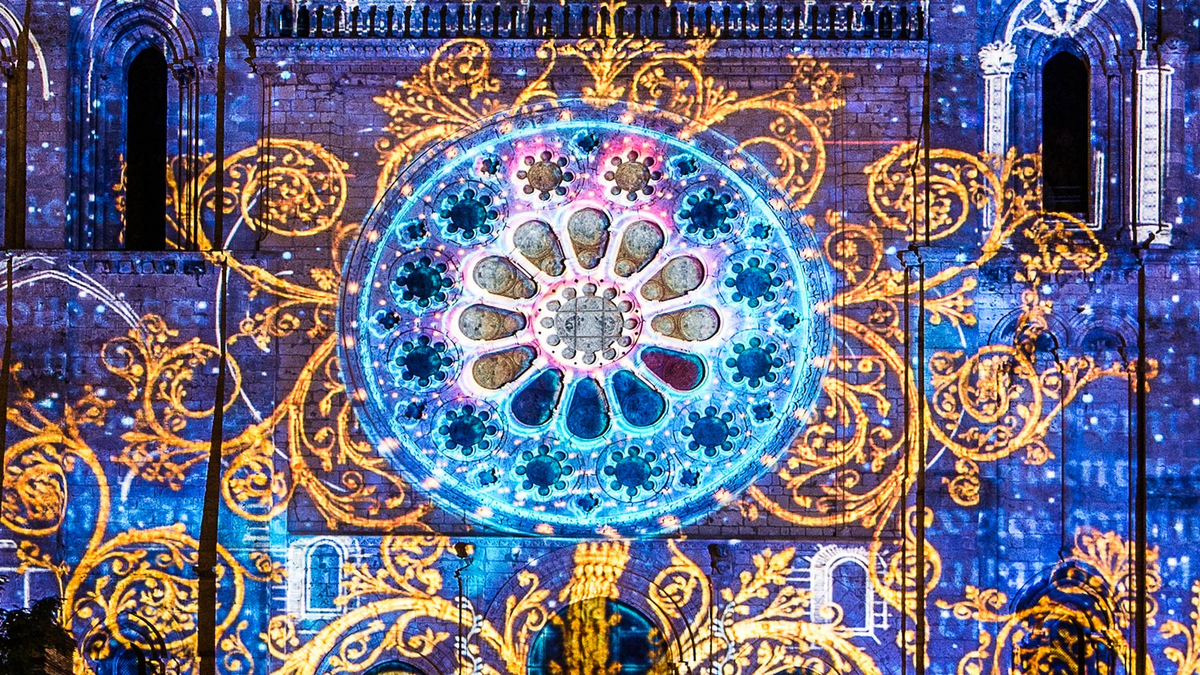

The show of the royal portal of the cathedral benefits from the most innovative technologies of video mapping. The creation benefits from an optimum luminosity and definition thanks to four 4K definition laser projectors of 32,000 lumens.

Animated scenography

This technique uses video mapping. Based on the architectural lines of the monuments, the videos unfold a scenario inspired by the monument, its history and its architecture. The animated scenographies are accompanied by a soundtrack. The lamps used operate with xenon or mercury and project HD digital images, stored on server media.

The show at the royal portal of the cathedral benefits from the most innovative video mapping technologies currently available. The creation benefits from optimum brightness and definition thanks to four 32,000 lumen 4K definition laser projectors. These projectors are the latest version of video mapping projectors. They consume less energy and have a longer life span than their predecessors.

The illumination of St. Peter's Church also required innovative equipment: three 32,000 lumen 4K projectors offer a resolution of 2,560 pixels x 1,600 pixels. A fourth projector with 12,000 lumens is dedicated to the illumination of the bell tower.

Energy efficiency

The City regularly invests in new equipment as it appears on the market, in order to obtain the finest and most qualitative projection quality possible: the pixel format is standardised on 4K. Scenographic quality is now accompanied by a virtuous character: lamp projectors are gradually being replaced by equipment that consumes 30 to 60% less energy, which also saves on operating and maintenance costs.

« Most of our equipment today is laser. In addition, public lighting is often switched off around certain shows. On the whole, the consumption is very moderate. And above all, while they are watching the show, the visitors do not consume at home. By integrating the consumption, we calculated that Chartres en lumières actually saved nearly 2 GWh of electricity per year. »

Laurent Lhuillery, conseiller municipal délégué à l’Animation de la Ville et à la Politique événementielle

The annual technical schedule

Every year, the Chartres en lumières team works hard to dazzle you from April to January. Discover the different stages of the installation.

March: reassembly phase of the structures

This begins with the reassembly of the metal projection towers and the semi-submerged platforms in the Eure and masts, where the projection and lighting equipment rests. In addition, the Chartres en lumières technicians ensure that the electrical connections of each site and the control room connections are working properly.

March to April: adjustment phase

The time for adjustment has arrived. For several weeks, our technicians program the shows and adjust the projection equipment so that the scenographies reveal their beauty to the public. This requires a synchronization between the parameters and the artistic supports. A meticulous work whose reward is to discover in preview the scenographies of Chartres en lumières.

April to October: launch of the event and the Festival of Light

From the beginning to the end of Chartres en lumières, technicians proceed to the daily start-up of the shows and to the follow-up of the quality of the rendering. Preventive and operational maintenance is carried out so that you can enjoy the experience to the fullest: change of artistic supports such as films or slides, for example. In September, it's the Festival of Light that requires all their attention for an evening more festive than ever.

December to January: launch of the Christmas scenographies

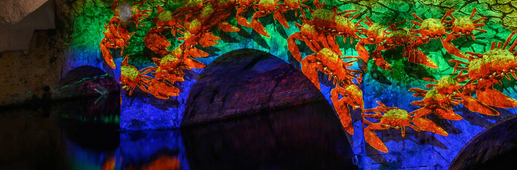

The end of year celebrations are an opportunity to propose new decorations on the main monuments: The royal portal of the cathedral, the Fine Arts Museum's facade of honor, the Saint-André collegiate church, the Minimes bridge, the Gloriette quay and wash houses, the Bouju bridge, the Foulerie wash house, the Saint-Hilaire arcades, the Saint-Hilaire bridge, the Grenouillère wash house, the Saint-Père bridge and, for the first time in 2022, the Montescôt Hotel.

January to March: dismantling of structures / maintenance, cleaning, repair and optimization

Chartres en lumières is now over. It is therefore time to dismantle the projection structures at the end of the season. The technical department is finalizing the complete dismantling of each device and is taking care of the projection devices. Change of mechanical parts, greasing, electronic and computer maintenance, refurbishing of the equipment... Nothing is neglected to give you more emotions year after year.

![[Translate to Anglais:]](/fileadmin/_processed_/3/5/csm_chartres-en-lumieres-calage-repetition-hotel-montescot_c4a07e0726.jpg)

![[Translate to Anglais:] [Translate to Anglais:]](

/fileadmin/_processed_/1/1/csm_chartrres-en-lumieres-bleu-6_40d2ac21f9.jpg

)

![[Translate to Anglais:] [Translate to Anglais:]](

/fileadmin/_processed_/1/9/csm_Conseil-departemental-madeleines-proust_7469637270.jpg

)

![[Translate to Anglais:] [Translate to Anglais:]](

/fileadmin/_processed_/0/2/csm_musee-beaux-arts-facade-honneur-CHartres-en-lumieres_4fe6cc5fb7.jpg

)

![[Translate to Anglais:] [Translate to Anglais:]](

/fileadmin/_processed_/a/8/csm_Eglise-Saint-Aignan-contemplation-CEL-2023_6cf7f247fa.jpg

)

![[Translate to Anglais:] [Translate to Anglais:]](

/fileadmin/_processed_/3/2/csm_Mille-pierres-M2EVENT-ST-PIERRE-4_40e6b94f84.jpg

)

Suivez-nous sur...